-

PROVIDE MACHINE

SOLUTION TO YOUR FABRICATIONFor Window door - Curtain Wall - Skylights - Glass

-

PROVIDE MACHINE

SOLUTION TO YOUR FABRICATIONFor Window door - Curtain Wall - Skylights - Glass

-

PROVIDE MACHINE

SOLUTION TO YOUR FABRICATIONFor Window door - Curtain Wall - Skylights - Glass

hot products

our products

about us

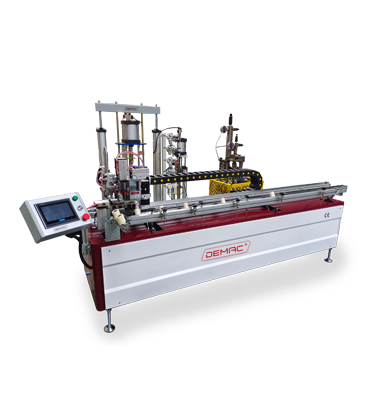

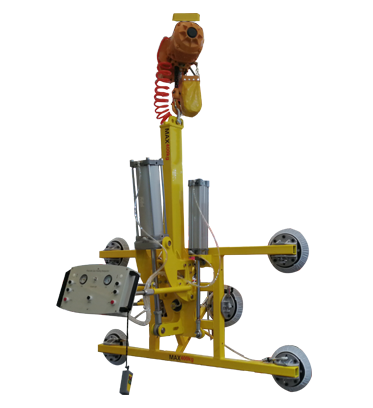

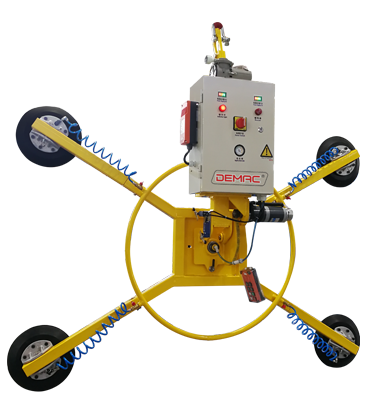

DEMAC, a leading manufacturer of Aluminum working machine, Glass processing related machine in China.

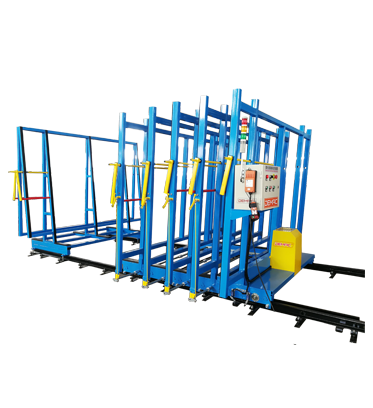

DEMAC is able to deliver an outstanding and exhaustive range of high end technological products such as Aluminum cutting Machine, CNC machining center, Curtain wall processing line, Glass Film Application Machine, Auto Mobile Glass Storage and handling System etc...

learn more-

0+

Country & Area

-

0+

Verified Happy Client

-

0+

Certified Engineer

-

0+

Products Series

our advantage

newslearn more

-

How to choose Raw Glass Storage Racks? 4Check the quality of single storage rack1. The wall thickness of the storage rack is not less than 3mm, which can provided stable and sufficient support2. The length of the glass support frame at the bottom of the rack should be sufficient, and its length should be longer than the total width of the glass to be placed. In some factories, in order to reduce costs, the length of the support frame is not enough, which increases the risk of later glass falling and damage.3. The thickness of the rubber pad on the bottom and back of the storage rack is 5mm, which should be flat and wear-resistant

-

How to choose Raw Glass Storage Racks? 3Check the steel thickness of the rail track and check whether the storage racks can be moved smoothly by manual As a part of mobile storage racks, track is ignored by many customers because it is fixed on the ground and does not directly contact glass. As the carrier of all storage racks, track has a great influence on the use of the storage rack.1. The thickness of steel plate for making track shall not be less than 8mm. Because the load-bearing of a single shelf is generally about 4T. If the thickness of rail steel plate is less than 8mm, slight deformation will easily occur in long-term use, which will affect the movement of the shelf.2. Check the track flatness. Regular manufacturers will have planing and aging treatment after track welding is completed3. Check the smoothness of the storage rack movement. The standard is that it is very easy to push each rack by hand, but the rack can not move after it is locked. The smooth movement of the racks proves that the track is flat and the design and installation of each shelf are reasonable. No additional resistance will be added to the motor and the service life of the motor will be prolonged.

-

How to choose Raw Glass Storage Racks? 21. See how the racks is installed on the railHow the storage rack is installed on the guide rail determines its stability and service life during use.The old type racks run on the rail, and the bottom is fixed by a small bearing. This installation structure is not 100% safe, and the small bearings are easily damaged after a period of use. Even some manufacturers use cheap bearings in order to reduce costs, which increases the risk of storage racks overturning.The new type storage racks run on the inner side of the rail and is directly wrapped and fixed by the rail, eliminating the risk of rollover from the root cause. There will be no damage to the accessories, reducing the use cost and prolonging the service life.

faqlearn more

CUSTOMER SERVICE ON LINE

If you have questions about the product can leave a message, we will reply to you for the first time